Diesel Oil AdditivesAdditives for Jet A1 and Marine FuelAdditives for Jet Fuel FSII (Fuel System Icing Inhibitor)Charcoal

Diesel Oil AdditivesAdditives for Jet A1 and Marine FuelAdditives for Jet Fuel FSII (Fuel System Icing Inhibitor)CharcoalDiesel Oil Additives are used in:

- sulphurless fuel oil containing less than 10 mg/kg;

-Ultra Low Sulphur Diesel

(both compliant with the norm EN 590:2009+A1:2010 and Worldwide Fuel Charter issue IV of September 2006)

It is recommended to add Lubricity Additives to Cetane Additives in order to gain maximum performance.

Recommended dosage:

Lubricity additive- 380 ppm

Cetane additive- 1000 ppm

In order to improve Diesel Oil quality it is crucial to add fuel additives:

1. Lubricity Additive improves lubricity;

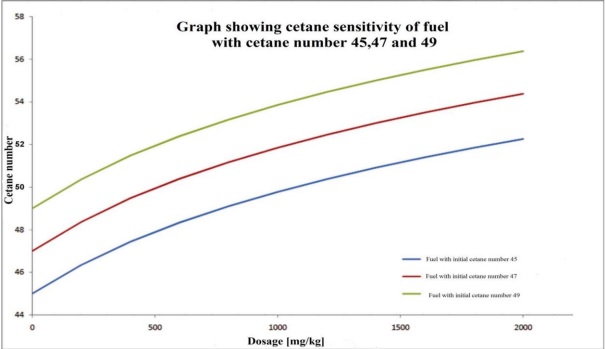

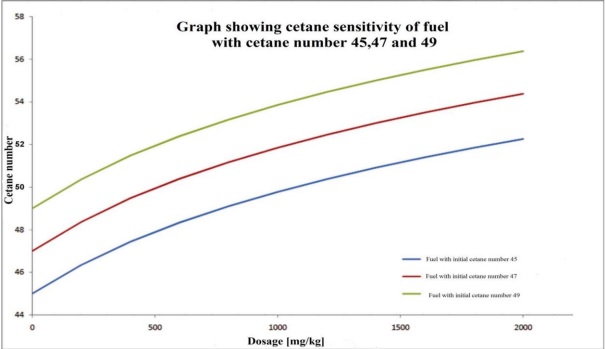

2. Centane Additive improves cetane number.

Lubricity additive

Jet A1 Additives

Marine Fuel Additive

Centane Additives

Diesel Oil Additive Petroxiten 43

Diesel Oil Additive Petroxiten 25

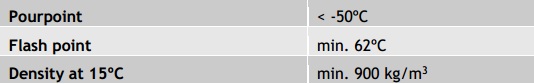

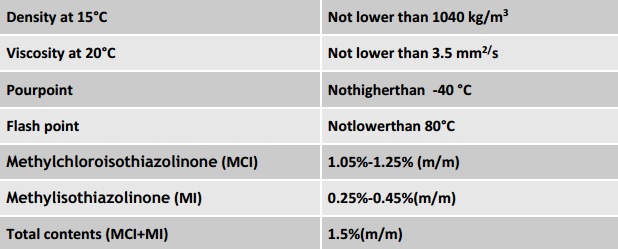

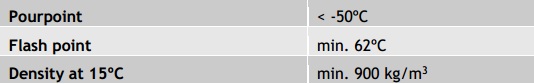

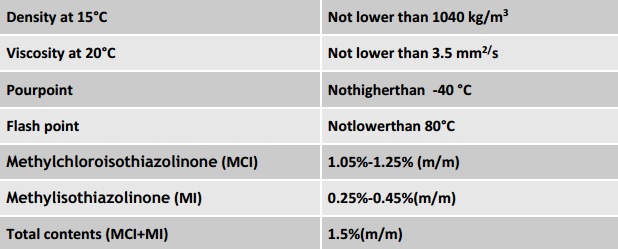

Technical requirements

Technical requirements

Technical requirements

Technical requirements

Technical requirements

Technical requirements

Technical requirements

Clean injector after using lubricity additives

Lubricity additives anti-foaming properties

Advantages of lubricity additive

-boosting lubricity;

-increasing detergent properties;

-preventing from corrosion;

-working as antifoaming agent;

-increasing oxidization resistance;

-decreasing emission of harmful substance in exhaust fumes;

-providing microbiological protection.

Advantages

-increases cetane number;

-boosts lubricity;

-increases detergent properties;

-increases engine power;

-reduces engine noise;

-reduces amount of smoke in fumes, -works anti-aging for an engine;

-reduces emission of NOx, CO, HC and dust.

Advantages

-works as biocide and antioxidant;

-contains fuel oil oxidation inhibitor and compatible biocides preventing fuel oil from

microbiological contamination;

-improves oxidative stability and long-term storage;

-effectiveness confirmed by research based on the norm ASTM E 1259:05;

-does not contain chlorine and heavy metals, -prevents form bio corrosion of the

storage tanks;

-is compatible with other fuel oil additives.

Advantages of Jet A1 Additive:

- works as biocide;

- prevents Jet A1 from microbiological contamination;

- prevents from turbidity, microemulsion, solid precipitate and slime;

- prevents from plugging of coalescent and fuel filters;

- effectiveness confirmed by research based on the norm ASTM D1655:2012;

- prevents the storage tanks and fuel system from microbiological corrosion of the

storage tanks;

- is compatible with other Jet A1 Additives.

Advantages of Marine Fuel Additive

-works as hydrogen sulfide scavenger;

-complies with norm ISO 8217:2012;

-improves safety during handling products containing hydrogen sulfide;

-minimizes toxic properties of hydrogen sulfide;

-prevents form corrosion caused by hydrogen sulfide;

-decreases emission of harmful and toxic hydrogen sulfide into environment.

Advantages of Fuel System Icing Inhibitor (FSII)

- lowers freezing point;

-prevents from blocking fuel filters and lines with ice crystals;

-works as biocide;

-stops bacterial growth in the fuel tank;

-complies with the norm ASTM D4171:11 and Military Specification:

MIL-DTL-85470B Inhibitor, Icing, Fuel System, High Flash Nato Code Number: S-1745 of 15 June 1999;

-recommended for aviation fuel JP-5 (Nato Code F-44), JP-8 (Nato Code F-34) and JP-8+100 (Nato Code F-37).

Widdringtonia cedarbergensis (Clanwilliam Cedar or Clanwilliam Cypress) is a species of Widdringtonia native to South Africa, where it is endemic to the Cederberg Mountains. It is a small evergreen tree growing to 5–7 m (rarely to 20 m) tall. The tree is widely known as the "Clanwilliam Cedar" but botanists have recommended the name Clanwilliam Cypress to better reflect its botanical relationships.

Minimum order quantity: 16 Ton (1x40 HC)

Packing for shipping: 25 kilos or 50 kilos bags

Properties of Marine Fuel Additive

Marine Fuel Additive binds hydrogen sulfide in gaseous form and transforms it into

liquid form (thio-compounds). Dissolved in fuel thio-compounds are durable and do not release hydrogen sulfide into gaseous form during proper storage, handling, transportation and reloading. Thio-compounds are combusted in a similar way as organic sulfides being components of the fuel.

Fuel System Icing Inhibitor (FSII) for aviation fuels prevents from formation of ice crystals in fuel lines. Jet Fuel can contain a small amount of dissolved water that does not appear in droplet form. As an aircraft gains altitude, the temperature drops and Jet Fuel's capacity to hold water is diminished.

Dissolved water can separate out and could become a serious problem if it freezes in fuel lines or filters, blocking the flow of fuel and shutting down an engine.

Marine Fuel Additive can be used for marine fuels of the following types:

1) destilate marine fuel (DMX, DMA, DMZ,DMB);

2) residual marine fuel (RMA,RMB,RMD, RME).

Advantages of Diesel Oil Additive Petroxiten 25

-works as biocide;

-contains stabilizers and compatible biocides preventing fuel oil from microbiological

contamination;

-prevents from turbidity, microemulsion, solid precipitate ans slime;

-improves thermo-oxidative stability;

-effectiveness confirmed by research based on the norm ASTM E 1259:05;

-does not contain chlorine and heavy metals;

-prevents the storage tanks and fuel system from microbiological;

-corrosion of the storage tanks, -is compatible with other fuel oil additives.

Paking:

- 200 liter drums

- 1000 liter containers

Paking:

- 200 liter drums

- 1000 liter containers

Paking:

- 200 liter drums

- 1000 liter containers

Storage:

Keep in tightly closed containers in roofed warehouses with temperature below 40°C.

Expiry date is 12 months from the date of manufacturing. After lapse of 12 months

the product may be used after checking if the product is still compliant with technical

requirements.

Storage:

Keep in tightly closed containers in roofed warehouses with temperature below 40°C.

Expiry date is 12 months from the date of manufacturing. After lapse of 12 months

the product may be used after checking if the product is still compliant with technical

requirements.

Storage:

Keep in tightly closed containers in roofed warehouses with temperature below 40°C.

Expiry date is 12 months from the date of manufacturing. After lapse of 12 months

the product may be used after checking if the product is still compliant with technical

requirements.

Diesel Oil AdditivesAdditives for Jet A1 and Marine FuelAdditives for Jet Fuel FSII (Fuel System Icing Inhibitor)Charcoal

Diesel Oil AdditivesAdditives for Jet A1 and Marine FuelAdditives for Jet Fuel FSII (Fuel System Icing Inhibitor)Charcoal